20年专注于精密火花机研发、生产!

提供一站式非标定制解决方案!

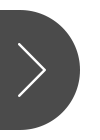

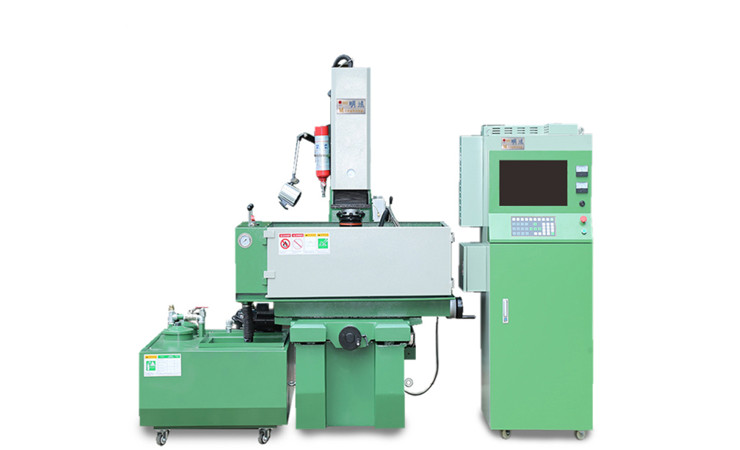

Mechanical characteristics of ZNC spark machine

The whole series is designed by CAD precision computer with high structural strength.

The spindle adopts DC servo motor to drive the precision ball tie rod imported from Taiwan to improve the precision and meet the requirements of high quality.

The machine tool has reasonable structure, no deformation and good rigidity to ensure the machining accuracy. The slide rail adopts V-shape and plane design. It slides lightly under heavy pressure, with precision grade bearings. The carriage adopts imported "TEFLON" guide rail veneer.

The lubrication system adopts recycling method, the sliding rail lubrication action is completed at one time, and the appearance is kept clean.

The worktable is subject to high cycle hardening heat treatment and grinded by a large imported precision grinder to ensure manufacturing accuracy and service life.

The casting material is HT300. After artificial aging and various treatments, it is durable and the accuracy remains unchanged.

System characteristics of ZNC spark machine

Provide more than 100 groups of file storage (mainly determined by the size of the internal hard disk), which can store 100 different molds or customer numbers. With point-to-point automatic shift function, memory means 100 * 40000 points.

A variety of special electrode materials (copper to copper, steel to steel, graphite to steel, copper to tungsten steel).

It has 10 sections of automatic refinement function, which can be: self editing, autoz automatic editing and intelligent conditional editing. The three editing methods can complete the processing from coarse → medium → fine at one time.

The slow jump two-stage slag discharge makes the large plane processing stable, the fire pattern of the working face uniform, and effectively improves the speed.

Programmed spindle runout enables the carbon slag of deep hole processing to be discharged smoothly, and effectively improves the efficiency of fine processing and deep hole processing.

The spindle is slowly lifted, which makes the large-area machining stable and the spark pattern uniform, and effectively improves the speed of large-area EDM.

The z-axis adopts Taiwan T-type screw linear guide rail, and the x.y-axis adopts imported ball screw linear guide rail and back clearance free bearing to ensure the positioning accuracy during processing, and the optical electronic ruler is used to feed back the accuracy monitoring system.

The newly designed power box and 15 "LCD (display screen) in line with European CE safety specifications can prevent dust, water and interference, and improve the service life of the electronic board.

Left and right stroke (mm)Spindle stroke (mm)Electrode load (mm)

Model specification | ZNC-750 | Electric box specification | ZNC Specifications |

X axis=700 | Screen display | 15 "CRT, color | |

Front and rear (mm) | Y axis=500 | Control system | Industrial computer |

Z axis=300 | Shift rate | 0.005M (per unit) x1, X5, x10 | |

Head stroke (mm) | Z 1 axis = 400 | Program file storage | 60 group |

Table size (mm) | 1100*600 | Maximum processing current (a) | 50 60 100 |

300 | Input power (kVA) | 4.5 6 10 | |

Workpiece load (mm) | 2000 | Maximum processing speed (mm / min) | 360 560 700 |

Maximum workpiece size (MN) | 1650*1100*900 | Optimum surface fineness (M RA) | 0.18 |

Outer diameter of oil groove (m) | 2000*1100*600 | Appearance dimension (mm) | 860*720*1950 |

Outer diameter of oil tank (mm) | 1800*1250*450 | Package size (mm) | 900*1000*2090 |

Oil tank volume (L) | 800 | Net weight (kg) | 210 |

Machine weight (kg) | 4000 | Set number of machining groups | 1 |

Set number of machining segments | 10 | ||

Processing mode | Machining up, machining down | ||

Shaking mode | nothing | ||

Maximum number of holes processed continuously | 1 individual |

ZNC 是手摇火花机: X、Y轴没有装马达,工作时需要人工手摇;电箱不具有自动移位功能,是一款手动操作的火花机。PNC是半自动火花机,X、Y轴都有马达装置,工作时是可以自动按程序设定的轨迹行走,不用人工手摇,这样可以省很多人力;电箱没有自动移位功能,是一款半自动火花机。CNC是全自动火花机,X、Y轴···