20年专注于精密火花机研发、生产!

提供一站式非标定制解决方案!

The main castings of the machine tool are made of high-grade cast iron. After annealing and vibration aging treatment, the internal stress of the castings is removed, the stability of the castings is greatly improved and not easy to deform;

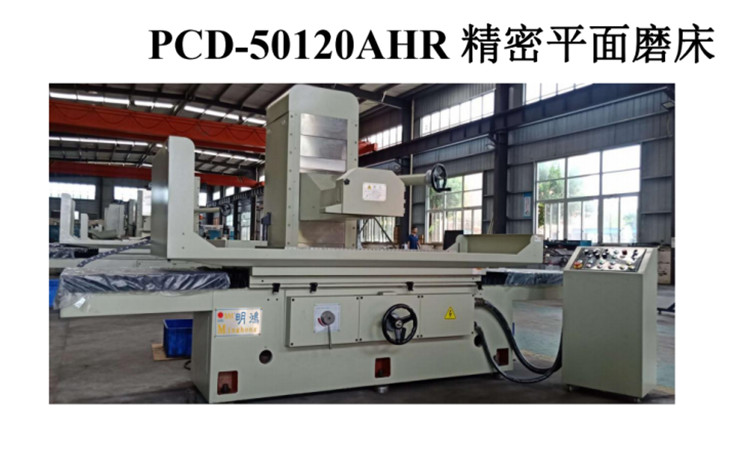

一、 Machine features:

1. The main castings of the machine tool are made of high-grade cast iron. After annealing and vibration aging treatment, the internal stress of the castings is removed, and the stability of the castings is greatly improved and not easy to deform;

2. In order to improve work efficiency, the company's machine tool has thick materials and stable body to meet the rigidity requirements of heavy cutting and fine grinding;

3. The guide rail is pasted with high-grade imported wear-resistant glue, which is manually and accurately spaded to ensure lasting accuracy;

4. Plane accuracy: 0.02mm; Swing of spindle arm end 0.003mm;

5. Grinding precision ball screw is adopted, which is lighter, more accurate and more durable;

6. The main components of the hydraulic system are independently designed with low vibration and noise;

8. The lubricating oil circuit has self-test, fault alarm, automatic circulation and equipped with pressure sensor to ensure that the guide rail is not short of oil.

Parameter table | Specifications parameter | unit | PCD-50120 |

ability | Working area of worktable(x*y) | mm | 500*1200 |

Maximum left and right movement(x) | mm | 1400 | |

Maximum movement before and after(Y) | mm | 570 | |

Maximum distance from worktable to spindle center | mm | 560 | |

Maximum bearing weight of workbench | kg | 2500 | |

workbench | T-groove of worktable | mm×N | 18*3 |

Table speed | m/min | 5-25 | |

Front and back structure | Feed of front and rear hand wheels (1 grid / 1 turn) | mm | 0.02/5 |

Front and rear automatic feed | mm | 0.1-8 | |

Fast forward and backward movement (50Hz / 60Hz) | mm/min | 990/1190 | |

grinding wheel

| Grinding wheel size | mm | 350*40*127 |

Grinding wheel speed (50Hz / 60Hz) | R.P.M | 1450/1740 | |

Upper and lower structure | Upper and lower hand wheel feed (1 grid / 1 turn) | mm | 0.005/0.2 |

Fast moving speed up and down | mm/min | 230 | |

motor | Spindle motor | HXP | 7.5*4 |

Upper and lower drive motors | W | 1/4*6 | |

Hydraulic motor | HXP | 5*6 | |

Flushing motor | W | 90 | |

Front and rear drive motors | W | 1/4*6 | |

size | Overall dimension of machine tool (length) × wide × High) | mm | 3500×2600×2100 |

Weight (approx.) | kg | ≈5300 |

ZNC 是手摇火花机: X、Y轴没有装马达,工作时需要人工手摇;电箱不具有自动移位功能,是一款手动操作的火花机。PNC是半自动火花机,X、Y轴都有马达装置,工作时是可以自动按程序设定的轨迹行走,不用人工手摇,这样可以省很多人力;电箱没有自动移位功能,是一款半自动火花机。CNC是全自动火花机,X、Y轴···